Kaneka XMAP™

Grades

| Cure type | Feature | Viscosity | |

|---|---|---|---|

| (Pa・s) | |||

| SA100S | Moisture Cure | Standard | 220 |

| OR110S | Oil resistance | 1100 | |

| RC100C | UV/Heat Cure | Standard | 160 |

| RC200C | Oil resistance | 530 |

Applications

- High UV resistant sealant for construction

- Glazing sealant

- Heat resistant adhesive

- Potting (Encapsulation)

- Liquid Gasket

- Oil resistant sealing

- Adhesive for electronics

- Concrete protection coating

- Modifier for resins

Features

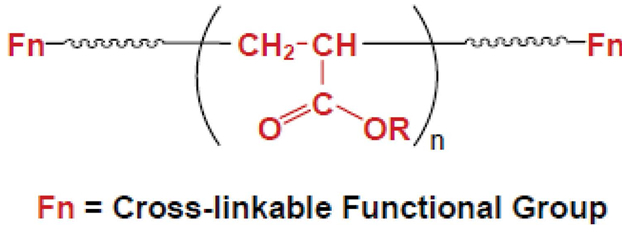

Novel • Reactive • Polyacrylate • Liquid Elastomer

- Liquid without Solvent at Room Temperature

- Controlled Polymerization – Low Polydispersity

- Cross-linkable Functional Groups at Both Ends

- Multiple Cure Methods (including UV/Moisture)

- High Performance Elastomer after Curing

- Very Low Compression Set without Post Cure

- Epoxy Resin Miscibility

- Oil Resistance

- Heat Resistance/Weatherability

- Minimal Shrinkage

- Impact Absorbance

- High Gel Percentage

- Expansion/Compression Durability

- Variety of molecular weight: Mn=5000 – 40000

- Low polydispersity: PDI=1.1 – 1.6 (most of grades: 1.1 – 1.3)

Structure of Kaneka XMAP™